On the day of the occurrence, the crew consisting of the student-pilot and the flight instructor performed a training flight. The take-off from the EPBC aerodrome took place at 15:051 hrs LMT and the planned flight time was 4 hours and 30 minutes. The flight was uneventful.

After returning to EPBC, the crew started the landing gear extension procedure. Despite moving the landing gear lever to the “down” position several times, the signal of the extended landing gear did not appear. In that situation, in accordance with “P2006T – Aircraft Flight Manual, Section 3 – Emergency procedures, LANDING GEAR SYSTEM FAILURES”, the procedure “EMERGENCY CHECKLIST LDG GEAR” was executed, but it ended in failure.

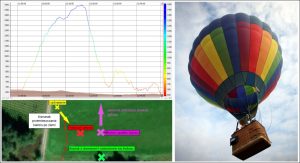

The crew reported landing gear problems to the flight coordinator on EPBC, and then performed a low pass over the aerodrome. Persons on the ground confirmed that the landing gear was not extended. After notifying the aerodrome services a fire assistance was provided and the crew landed with the landing gear retracted on a grass runway, damaging the lower fuselage skin.

Causes of the accident:

Inappropriate components used by the manufacturer of the Tecnam P2006T aircraft in the landing gear extension and retraction system.

Contributing factors:

1) Errors in the alternate landing gear extension procedure.

2) Insufficient securing of the lever mounted on the shaft of the FIRST DISCHARGE valve against spontaneous loosening.

Safety recommendations:

During the investigation of the occurrence, the PKBWL determined that the technical solutions applied in the landing gear extension and retraction system of Tecnam P2006T aircraft create hazards to the flight safety and, therefore, should be immediately modified as described below in the detailed recommendations.

1) Recommendation 2022/2456/1

The value of the current of the hydraulic pump motor of the landing gear in some situations exceeds the value of the rated current of the components used in this circuit, which causes fusing of the relay contacts and overheating of the connector on the hydraulic pump motor.

Therefore, PKBWL recommends that the manufacturer of the Tecnam P2006T airplanes analyses the parameters of the components used in the landing gear retraction and extension system, and then replaces all system components whose load is higher than their rated currents values.

2) Recommendation 2022/2456/2

During the investigation the PKBWL determined that if during aircraft operation, the relay contacts in the circuit of the landing gear hydraulic pump motor are fused, or the landing gear lever is blocked in the upper position, the hydraulic pump works and maintains the pressure in the system (despite opening the FIRST DISCHARGE valve), which prevents the landing gear from being extended by the alternate system. In such case, the pressure can be reduced only by pulling out the “LANDING GEAR” circuit breaker.

For the above reasons PKBWL proposes that the manufacturer of Tecnam P2006T airplanes considers a modification of the alternate landing gear extension procedure by adding a provision that in such a need the LANDING GEAR circuit breaker must be pulled out and that the abovementioned circuit breaker must be appropriately marked.

3) Recommendation 2022/2456/3

During the investigation PKBWL determined that the lever mounted on the shaft of the FIRST DISCHARGE valve is insufficiently secured against spontaneous loosening. This fact was revealed on the serious incident aircraft. Loosening of the lever allows for its free rotation around the valve shaft, which prevents the valve opening and reduction of the pressure in the system prior to opening THEN EMERGENCY valve.

Therefore, PKBWL recommends that the manufacturer of the Tecnam P2006T aircraft modifies the connection of the FIRST DISCHARGE valve lever with the valve shaft to prevent its spontaneous loosening during operation of the aircraft (e.g. use a splined joint).

4) Recommendation 2022/2456/4

Implementation of recommendations 2022/2456/1, 2022/2456/2 and 2022/2456/3 requires time, but irregularities found during the investigation may result in the inability to extend the landing gear via alternate system, which poses a real hazard to flight safety.

Therefore, PKBWL recommends that the manufacturer of the Tecnam P2006T aircraft, issues a service letter/bulletin informing aircraft users about the above problems and defining a temporary solutions, until the above recommendations will have been implemented.